Working principle of CEMS flue gas online analysis system

Author: Baisirui (Hebei) Electric Heat Tracing Co.

Origin:

Time:2021-11-02 14:24

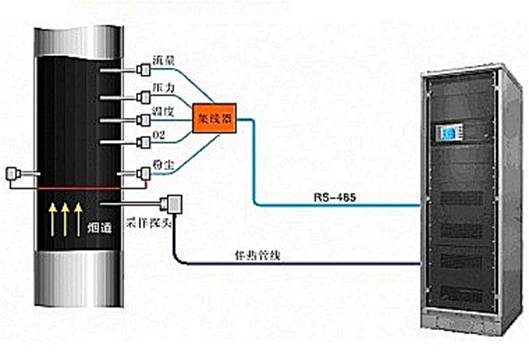

CEMS flue gas online analysis system working principle:

CEMS flue gas online analysis system extracts flue gas through electric heating type direct extraction probe, after dust removal heating (120~180℃), heat preservation (more than 120℃) link, the sample gas is guided to the pretreatment system (mainly to remove particulate matter, H2O/corrosive gases, corrosive gases, etc.), and then transported to the analyzer by the sample gas control system for analysis.

The CEMS flue gas online analysis system continuously measures the concentration of SO2 in flue gas by using the change of infrared absorption of SO2 near 7.3μm (7300nm) in the infrared region, and the concentration of NO in flue gas by using the change of infrared absorption of NO near 5.3μm. NO2 is converted to NO by the reduction converter and then measured. The change of magnetic declination angle caused by oxygen is converted into a current signal, and the strength of this signal is linearly related to the concentration. The high quality manufacturing process and design ensure accurate measurement of the system.

Related News

undefined

All rights reserved:Baisirui (Hebei) Electric Heat Tracing Co. Powered by 300.cn Label Privacy statement